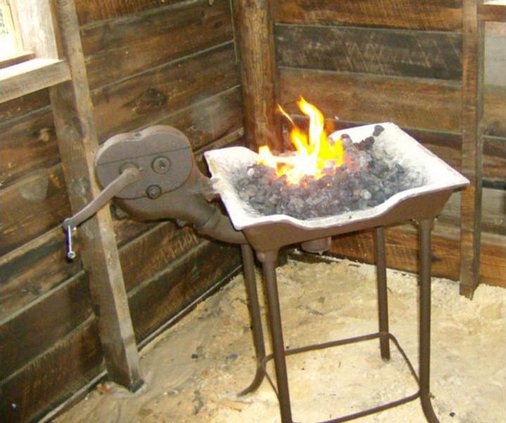

Historic Effingham Society’s Living History Site is proud of its new blacksmith shop that will be on display during Olde Effingham Days.

In the traditional blacksmith’s shop, coal is burned in a forge using a bellows which compresses air to add oxygen to the fire resulting in a fire hot enough to superheat or melt metal. The red hot metal is carefully shaped, using a hammer on an anvil, into implements including: horseshoes, branding irons, nails, andirons, etc.

An example of an item made in a blacksmith shop is the Futrelle plow. Micajah Benjamin Futrelle, born in Effingham in 1839, served throughout the entire Civil War for the Confederacy, enlisting at age 22. After his return to the county following the war, his family reports that he was a blacksmith. He designed the Futrelle plow.

We have copies of his pattern designing the plow and sweeps in our museum files. This two-sweep plow was drawn with a single mule and was used to “lay corn by” according to farmers in the area. Mr. Futrelle’s great-grandson, Richard Loper, provided some copies of orders and invoices for “Futrelle sweeps” ordered and shipped from Southern Plow Company in Columbus in 1924. These documents are from Richard’s wife, Wilena Smith Loper’s father, Mr. W. W. Smith, who ran a business in Clyo. He ordered 61 Futrelle sweeps for $36.50 including shipping and labor. It appears that this plow, designed by an Effingham blacksmith, was mass produced by the Southern Plow Company.

Please visit Historic Effingham Society’s Museum and Living History Site during Olde Effingham Days on April 21, from 10 a.m. until 5 p.m. to see the blacksmith’s shop and much more.

This article was written by Susan Exley of Historic Effingham Society. Please send comments, photos or information to her at 754-6681 or email: susanexley@historiceffinghamsociety.org.