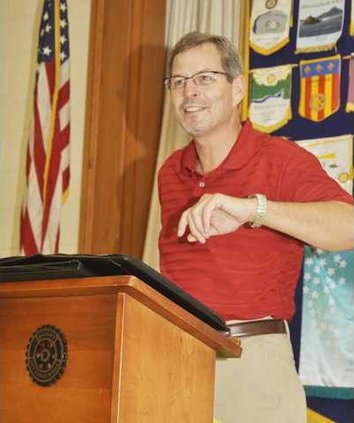

Safety has taken a step forward at Georgia-Pacific’s Savannah River Mill, plant manager Kelly Wolff said. In remarks Thursday to the Rotary Club of Effingham County, Wolff said safety at the plant has improved and they also are getting closer on reducing and eliminating the smell. “We had a safety performance that was not where we wanted it to be,” he said.

Manager: Mill running strong and safely